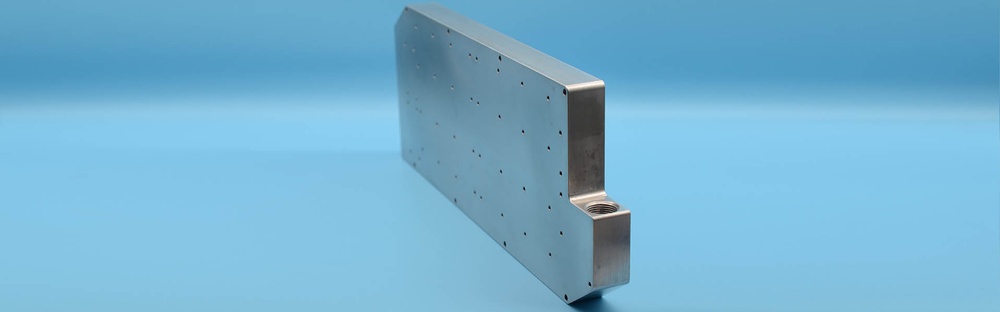

Liquid Cold Plate For Power Conversion System (PCS) for Energy Storage

- Innovative Thermal Solutions

Categories: Air Cooled Heat Sinks Bonded Fin Heat Sinks CNC Machining CNC Milling Cold Plate Manufacturer Cooling Solutions for Electronics Industries Copper Heat Sinks Design Experts Electronics Manufacturing Embedded Heat Pipe Engineering Firm Engineers Extruded Heat Sinks Friction Stir Welding Heat Pipes Heat Sink Products Heat Sink Solutions Heat Sinks Heatsink Manufacturer Hypercool Coldplate Liquid Cooled Heat Sinks Manufacturing Experts Manufacturing Firm Pressed-in Tube Coldplate Skived Fin Heat Sinks Solid State Refrigeration Thermal Systems Thermal Design Thermal Engineering Thermal Experts Thermal Management Thermal Management Products Thermal Management Solution Provider Thermal Manufacturing Thermal Solutions Two-phase Thermosyphon Assemblies

THE CHALLENGE

High Performance Liquid Cold Plate for Power Electronics

Design high performance cold plate to cool next generation energy storage. Extensive CFD modeling for the flow distribution results in excellent uniform temperature. And minimize the temperature under the IGBTs.

DESIGN AND MANUFACTURING

Optimize Thermal and Hydraulic Performance

- Working closely with the customer to determine thermal and mechanical boundary conditions for their particular application.

- Create a thermal model for the cold plate design.

- Optimize the design thermally and hydraulically to meet or exceed the boundary conditions.

- Designing for manufacturability.

- Periodic design review meetings with the client to be sure that the design is meeting or exceeding expectations.

RESULTS

Uniform Temperature Distribution