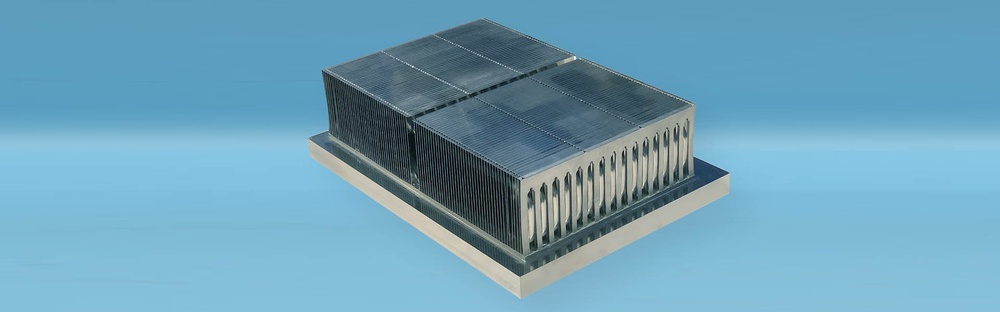

Air Cooled Heat Sink for High Power RF Amplifiers

- Innovative Thermal Solutions

Categories: Air Cooled Heat Sinks Bonded Fin Heat Sinks CNC Machining CNC Milling Cold Plate Manufacturer Cooling Solutions for Electronics Industries Copper Heat Sinks Design Experts Electronics Manufacturing Embedded Heat Pipe Engineering Firm Engineers Extruded Heat Sinks Friction Stir Welding Heat Pipes Heat Sink Products Heat Sink Solutions Heat Sinks Heatsink Manufacturer Hypercool Coldplate Liquid Cooled Heat Sinks Manufacturing Experts Manufacturing Firm Pressed-in Tube Coldplate Skived Fin Heat Sinks Solid State Refrigeration Thermal Systems Thermal Design Thermal Engineering Thermal Experts Thermal Management Thermal Management Products Thermal Management Solution Provider Thermal Manufacturing Thermal Solutions Two-phase Thermosyphon Assemblies

THE CHALLENGE

Cooling High Power RF Equipment

Designing an efficient air-cooled heatsink to cool next-gen RF technology, powered by high-flux transistors. Extensive CFD modelling to ensure all devices are cooled simultaneously within the packaging constraints set out by the client

THINKING OUTSIDE THE BOX, COOLING IN THE BOX

Cooling High-Flux Devices using air-cooled heat pipe technology

- Quantified the design and boundary conditions with existing air-cooled designs to benchmark the performance requirements over “Traditional” air cooled technologies.

- Working closely with the customer to determine thermal and mechanical boundary conditions for their application.

- Creating a fully functional CFD model to simulate the client design accurately.

- Optimizing the mechanical and thermal design. Maximizing the thermal performance of the heat sink within the mechanical boundary conditions laid out by the clients.

- Designing for manufacturability.

- Periodic design meetings with the client and the manufacturing team to ensure all stakeholders are confident in the design, its performance, and manufacturability within the client’s budgeted cost.

RESULTS

Cooling all high flux designs

- Cooled RF power transistors with a heat flux of 40 W/cm2

- Total cooling of 1.8 kW in limited space

- Optimized fin spacing to maximize flow rate from the fan

- Applied the use of heat pipes to boost fin efficiency and baseplate heat spread from the high flux devices

- ITS Solution: 20°C temperature reduction, reducing the heat sink thermal resistance by 32%